Introduction

Direct burial power cable is a crucial component of electrical infrastructure that provides safe and reliable power transmission for a variety of applications. Whether used in residential, commercial, or industrial settings, direct burial power cable plays a vital role in ensuring a consistent and efficient flow of electricity. In this comprehensive guide, we will delve into the various aspects of direct burial power cable, exploring its benefits, considerations, installation processes, and maintenance requirements.

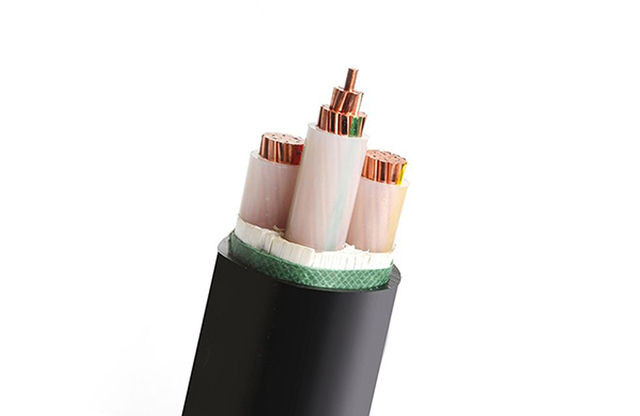

Overview of Direct Burial Power Cable

Direct burial power cable, also known as underground cable, is specifically designed for installation in the ground without the need for additional protection such as conduit or ducts. This type of cable is engineered to withstand the harsh underground environment, including exposure to moisture, soil conditions, and potential mechanical damage. Direct burial power cable is commonly used for outdoor applications where traditional above-ground wiring is impractical or aesthetically undesirable.

Benefits of Direct Burial Power Cable

1. homepage : Direct burial power cable is manufactured with materials and construction techniques that make it highly durable and resistant to environmental factors such as moisture, temperature fluctuations, and physical damage. This durability ensures long-term reliability and reduced maintenance requirements.

2. Cost-Effectiveness: While the initial installation cost of direct burial power cable may be higher than traditional above-ground wiring, the long-term cost savings can be significant. Because underground cables are less susceptible to damage from weather, vandalism, or accidental impacts, they generally require less maintenance and repair over time.

3. Aesthetics: Direct burial power cable offers a more aesthetically pleasing option for power distribution, particularly in residential areas or landscaped environments where above-ground wiring may be unsightly or disruptive. By burying the cables underground, the visual impact is minimized, enhancing the overall appearance of the surroundings.

4. Safety: Underground cables are inherently safer than above-ground wiring systems, as they are not exposed to risks such as falling branches, vehicle accidents, or vandalism. This increased level of safety is especially important in public spaces or high-traffic areas where the risk of electrical hazards is a concern.

Considerations for Direct Burial Power Cable Installation

1. Cable Selection: When choosing a direct burial power cable, it is essential to consider factors such as voltage rating, conductor size, insulation type, and environmental conditions. Selecting the appropriate cable specifications based on the specific application requirements is crucial to ensure optimal performance and longevity.

2. Depth of Burial: The depth at which direct burial power cable should be installed varies depending on local building codes, soil conditions, and the presence of other utilities. In general, cables should be buried at a depth that provides adequate protection from excavation activities, frost heave, and other potential threats.

3. Conduit and Duct Requirements: In some cases, it may be necessary to install conduit or ductwork to protect direct burial power cable from sharp objects, rocks, or other potential hazards. Conduit can also facilitate future cable replacement or upgrades by providing a pathway for pulling new cables through the underground system.

4. Grounding and Bonding: Proper grounding and bonding practices are essential for ensuring the safety and effectiveness of direct burial power cable installations. Grounding electrodes should be installed at regular intervals to dissipate electrical faults and prevent the buildup of dangerous voltages in the system.

Installation Process for Direct Burial Power Cable

1. Site Preparation: Before installing direct burial power cable, the installation site must be properly prepared to ensure a smooth and efficient process. This may involve excavating trenches, removing obstacles, and compacting the soil to create a suitable environment for laying the cable.

2. Cable Layout: The layout of the direct burial power cable should be carefully planned to optimize efficiency and minimize the risk of damage during installation. Cables should be laid in straight lines whenever possible, with gentle bends and gradual changes in direction to reduce stress on the conductors.

3. Cable Protection: To protect direct burial power cable from damage during installation and throughout its operational life, various protective measures can be implemented. This may include the use of warning tape, marker tape, or cable markers to indicate the presence of buried cables and prevent accidental digging or excavation.

4. Cable Splicing and Termination: Proper splicing and termination techniques are essential for ensuring the integrity and reliability of direct burial power cable connections. Splices should be made using approved methods and materials to maintain electrical continuity and prevent moisture ingress.

Maintenance of Direct Burial Power Cable

Regular maintenance is essential to ensure the continued performance and safety of direct burial power cable installations. Some key maintenance tasks include:

1. Visual Inspections: Periodic visual inspections of direct burial power cable can help identify signs of damage, deterioration, or other issues that may require attention. Inspections should be conducted by qualified personnel using appropriate safety equipment and procedures.

2. Testing and Monitoring: Routine testing and monitoring of underground cable systems can help detect potential faults or performance issues before they escalate into major problems. Electrical tests such as insulation resistance testing and fault location can pinpoint areas of concern and guide maintenance efforts.

3. Grounding Checks: Grounding systems associated with direct burial power cable installations should be inspected regularly to ensure proper functionality and compliance with relevant standards. Grounding electrodes, connections, and conductors should be tested for continuity and resistance to verify effective grounding.

4. Cable Repairs and Replacements: In the event of cable damage or failure, prompt repairs or replacements should be carried out to restore the integrity and functionality of the system. Repairs should be performed by qualified personnel using approved materials and techniques to maintain safety and performance standards.

Conclusion

Direct burial power cable offers a range of benefits for power transmission applications, including durability, cost-effectiveness, aesthetics, and safety. By understanding the considerations for installation, following best practices during the installation process, and implementing a comprehensive maintenance plan, users can ensure the long-term performance and reliability of underground cable systems. With proper planning, installation, and maintenance, direct burial power cable can provide a dependable power distribution solution for a wide range of residential, commercial, and industrial applications.